Categories

Recent Posts

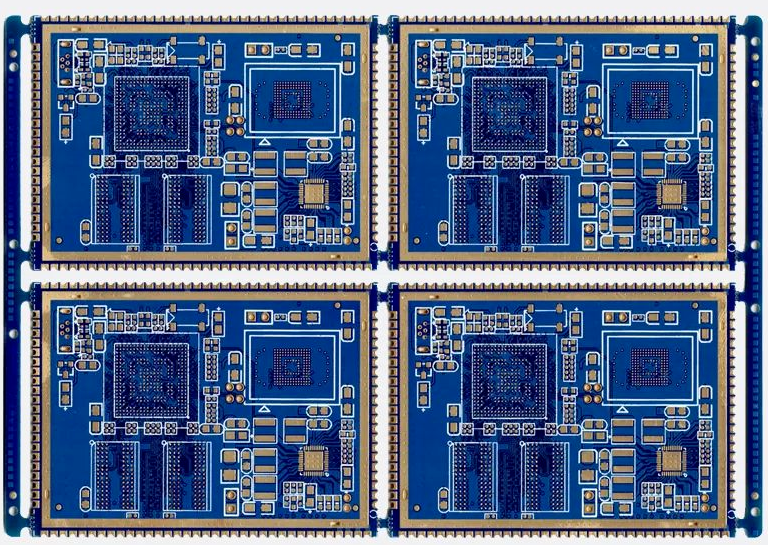

In the process of making PCB circuit boards, Panelization is a key link, which directly affects the production efficiency and utilisation of circuit boards. Different Panelization methods can to a certain extent optimize the layout of the circuit board, improve the efficiency of material utilization, so as to achieve better production results. Today, we will discuss in detail the specific types of PCB panelization and its characteristics.

1. Spaceless Panelisation

Pitchless Panelization is a type of Panelization that is characterised by the removal of spacing between small cell PCB boards, using V-CUT or stamp hole separation. In this way, there will be no spacing between the small cells of PCBs in the board, which may result in a PCB profile outside the expected range. Panelization without spacing is therefore suitable for PCB designs with less stringent form factor requirements, but it is recommended to avoid this type of panelisation if the form factor is more stringent.

2. Annular PCB panelization

The annular PCB panelization method maximizes single-board utilization rates and minimizes gaps between boards. In this approach, engineering preparation personnel arrange small-unit PCB modules in a predefined pattern to reduce blank areas to the greatest extent possible, thereby optimizing material utilization efficiency. This technique effectively reduces material waste while enhancing production efficiency.

3. Inverted Panel (Reverse-Fold Panelization)

The inverted panel method combines annular panelization with a specialized rotated 180° folding technique, where small-unit PCB modules are arranged in L-shaped or T-shaped interlocking configurations. This approach optimizes template space utilization, enabling tighter layouts and maximizing material efficiency.

4. Macro-Driven Panelization

Macro-driven panelization uses pre-programmed macro instructions. Engineers first import the maximum outline dimensions of individual PCB units into software, then execute panel assembly via click-to-panelize operations. Advantages include:

5. Hybrid Panelization

Hybrid panelization optimizes combinations of aforementioned methods. Engineers select different techniques based on practical requirements to leverage their respective strengths, thereby improving panel utilization and single-board yield. Flexible integration of multiple panelization approaches enables enhanced layout optimization and production outcomes.

Summary of key comparisons

Comparison dimension

Best option

Conditions of application

Material utilisation

Macro-Driven panelization(>95%)

Multiple varieties, small batch

Processing efficiency

Spaceless panelisation

Standardised small PCBs

Thermal requirements

Inverted panel

High Power PCB

Shaped PCBs

Annular PCB panelization

Round/Oval PCB

Complex product line

Hybrid panelization

Multi-layer + shaped combinations

Panelization is an important part of the PCB production process that needs to be seriously considered and solved. Different Panelization methods have different advantages and applicable scenarios, engineers need to choose the appropriate Panelization method according to the actual needs to ensure the production of high-quality PCB boards.

If you have any demands or questions about PCB panelization, please feel free to contact us, we will provide you with one-stop service.

Email : Sales@ucreatepcb.com

Welcome to consult our sales engineer with BOM list and Gerber file