Categories

Recent Posts

HotBar working principle:

Pulsed thermal compression soldering is also known as Haba soldering (HotBar), also known in the industry as Haba machine (HotBar), HotBar process is a kind of heat and pressure will be flexible circuits (FPC) or flexible and rigid combination of boards soldered to the rigid PCB key process, widely used in electronics manufacturing (such as mobile phones, tablets, wearable devices).

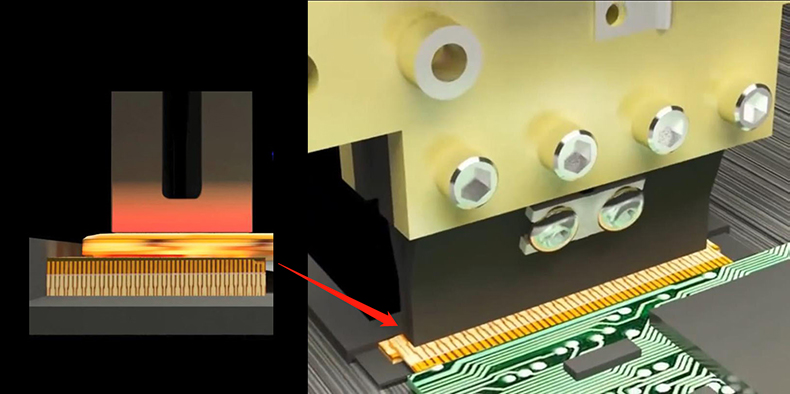

The principle of operation is to print the solder paste on the circuit board (PCB) pad, after the soldering furnace will melt the solder paste and pre-soldered on the circuit board, and then the object to be soldered (generally FPC) placed in front of the tin melted once on the PCB pad, through the hot pressure head loaded with a certain pulse voltage, the hot pressure hair heat, will be connected with the object to be warmed up, when the temperature rises to the melting point of the solder (i.e., rise to the pre-set temperature), will be connected with the object to be soldered to a rigid PCB. When the temperature rises to the melting point of the solder (i.e. to a pre-set temperature), the solder melts between the objects connected to it and connects them together.

HotBar is usually a flexible board (FPC) soldered to the PCB, in order to achieve light, thin, short, small purpose, but also can effectively reduce costs, because you can use less 1 ~ 2 flexible board connector (FPC connector).

Features:

Hotbar is mainly used in devices that can not be soldered using a normal SMT + reflow oven for soldering operations, and the use of soldering iron for soldering is prone to inconsistent appearance of the weld, uneven, easy to false soldering as well as easy to weld the product. The pulse hot press is different from the constant temperature soldering iron, the pulse hot press can reach the desired temperature instantly when the power is turned on, and once there is no voltage applied to both ends of the soldering head, the temperature can reach room temperature instantly; and the soldering head is flat, so the appearance of the soldering out of the flat and consistent, and there is rarely a bad soldering.

HotBar process control

1. Temperature control

Pressure head temperature: need to be higher than the melting point of the solder (lead-free solder is usually 220-250 ° C, leaded solder 180-220 ° C), controlled in stages:

Preheating stage: Slowly increase the temperature to avoid thermal shock and reduce the deformation of FPC.

Soldering stage: accurately maintain the target temperature (±5°C) to ensure that the solder is fully wetted.

Substrate protection: high temperature zone time control (usually 1-5 seconds) to avoid FPC/PCB delamination or deformation.

2. Time control

Hot press contact time: typical value 3-10 seconds, too short a time leads to cold soldering, too long to trigger oxidation or thermal damage.

Cooling time: natural cooling or forced air cooling to avoid solder joint disturbance.

3. Control the gap between the hot press head and the object to be pressed (usually PCB).

When the hot press head descends to the object to be pressed, it must be completely parallel to the object to be pressed, so that the object to be pressed will be heated evenly. The general practice is to loosen the screws that lock the head on the press, then set it to manual mode, lower the head and press it against the object to be pressed, make sure that it is in full contact, then lock the screws, and finally raise the head. Usually the object to be pressed is PCB, so the hot press head should be pressed on the PCB, and it is better to find a piece of un-tinned board to adjust the machine.

4. Control the fixed position of the object to be pressed.

Generally the object to be pressed is PCB and soft board, need to make sure that PCB and soft board can be fixed on the fixture carrier, and need to make sure that the position is fixed every time the HotBar is pressed down, especially the front and back direction. The lack of a fixed position of the hotbar may cause empty soldering or damage to nearby parts. In order to achieve the purpose of fixed to be pressed, the design of PCB and flexible PCB (FPC), pay special attention to increase the design of positioning holes, the location of the best in the vicinity of the melting tin hot press, in order to avoid the downward pressure when the FPCB shift.

5. Control the pressure of the hot press.

Please refer to the recommendations provided by the hot press manufacturer.

6. Do I need to add flux to the HotBar?

Flux can be added to facilitate smooth soldering. Of course, it is better to achieve the goal without adding flux. Because the flux in the solder paste has evaporated after it has been printed on the board and passed through the reflow oven, it is usually necessary to add flux again when pressing the HotBar to improve its soldering ability. The purpose of the flux in the removal of oxides, because it is printed on the circuit board before the paste, after a certain period of time in contact with the air, will produce oxides on the surface, and there are many impurities in the air, organic matter, which will affect the quality of the soldering, so HotBar soldering are generally used again flux in order to facilitate the soldering smoothly.

Welcome to consult our sales engineer with BOM list and Gerber file